Page 18 - ISCAR_WORLD_2021

P. 18

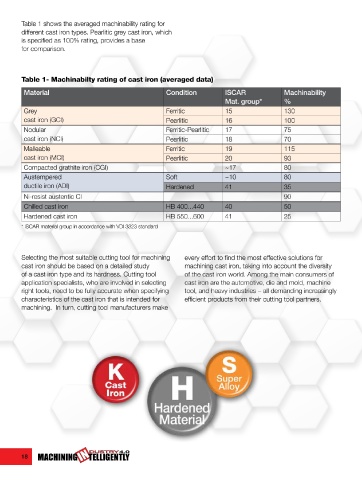

Table 1 shows the averaged machinability rating for

different cast iron types. Pearlitic grey cast iron, which

is specified as 100% rating, provides a base

for comparison.

Table 1- Machinabilty rating of cast iron (averaged data)

Material Condition ISCAR Machinability

Mat. group* %

Grey Ferritic 15 130

cast iron (GCI) Pearlitic 16 100

Nodular Ferritic-Pearlitic 17 75

cast iron (NCI) Pearlitic 18 70

Malleable Ferritic 19 115

cast iron (MCI) Pearlitic 20 93

Compacted grathite iron (CGI) ~17 80

Austempered Soft ~10 80

ductile iron (ADI) Hardened 41 35

Ni-resist austentic CI 90

Chilled cast iron HB 400...440 40 50

Hardened cast iron HB 550...600 41 25

* ISCAR material group in accordance with VDI 3323 standard

Selecting the most suitable cutting tool for machining every effort to find the most effective solutions for

cast iron should be based on a detailed study machining cast iron, taking into account the diversity

of a cast iron type and its hardness. Cutting tool of the cast iron world. Among the main consumers of On a firm basis which enables a considerable increase in cutting

application specialists, who are involved in selecting cast iron are the automotive, die and mold, machine The previously mentioned difficult-to-cut hard/ speeds. In machining hard cast iron, for instance, the

right tools, need to be fully accurate when specifying tool, and heavy industries – all demanding increasingly high chrome cast iron produces serious barriers for speeds are 2-5 times higher when compared with

characteristics of the cast iron that is intended for efficient products from their cutting tool partners. machining productivity. A cutting tool experiences high cemented carbide. ISCAR's high-performance milling

machining. In turn, cutting tool manufacturers make

mechanical and thermal loading. In milling this cast cutters carrying tangentially clamped inserts with CBN

iron by cemented carbide tools, for example, a typical tips are extremely popular in the automotive industry.

cutting speed is low: 40-50 m/min (130-160 sfm). For hard turning applications, the company expanded

Intensive heat generation often forces manufacturers to the range of CBN tipped ISO-type inserts for both

apply wet coolant. As a result, the tool operates under continuous and interrupted cut

conditions of a heat shock effect, which considerably

shortens the tool life. In ISO K applications (machining grey, nodular and

malleable cast iron) in medium-duty loading, ceramic

ISCAR developed the DT7150 grade especially for tools have demonstrated good results. Peripherally

this type of operation. DT7150 is a "DO-TEC" carbide ground tangentially clamped TANGMILL milling

grade that has a tough substrate and combines inserts, made from the silicon nitride (Si3N4) grade

medium-temperature CVD and PVD coating processes. IS8, ensures increasing cutting speed up to 3 times

Due to its extremely high wear and chipping resistance, and provide excellent surface finish. In turning, cutting

DT7150 provides customers with an effective tool speeds of up to five times faster can be achieved by

material for cutting hard cast iron. using the CVD-coated silicon nitride inserts, even for

A fundamental significant change in productivity can roughing operations.

be reached with the use of cubic boron nitride (CBN),

DUSTRY 4.0

18 MACHINING IN TELLIGENTLY ISCAR 19