In the metalworking industry, ensuring a high-grade surface finish has always been one of the main directions in cutting tool development. This is also true for indexable face milling cutters.

Despite significant improvement in the high surface quality of milled surfaces, tool designers still believe that available resources have not yet exhausted and that intelligent applications of the last generations of advanced milling cutters can substantially improve surface texture.

When considering an indexable milling cutter, the key factors that determine the quality of a generated surface are the cutter’s geometry and accuracy. Both characteristics are mainly related to inserts carried by the cutter.

Powder metallurgy processing has enabled producing carbide inserts with complex shapes, ensuring optimal cutting geometry while maintaining substantially increased accuracy of inserts as sintered inserts. Not surprisingly, such advancements in technology have significantly improved the surface finish in face milling. However, when indexable milling cutters were successfully applied to machining high-strength materials, and manufacturers started to notice hard milling as an alternative to grinding, the metalworking industry started demanding higher surface finish grades provided by milling.

An indexable face milling cutter is a multi-tooth tool. More teeth = more productivity. This is an undeniable advantage of the cutter. But, in terms of surface texture, a large number of teeth may be a problem. A fine distinction in teeth protrusion leads to irregular feed for the teeth and contributes to chatter, which will ultimately affect the surface finish.

It is perfectly clear that insert accuracy can considerably be increased by grinding. Moreover, grinding provides a sharp cutting edge that is very important in maintaining cutting action and preventing plastic deformation of metal in fine milling, which features shallow depths of cut. Ensuring a highly accurate cutting edge requires grinding both the top and side surfaces of an insert. This may cancel the advantages of powder metallurgy in generating complicated surfaces to provide required rake and clearance angles along a cutting edge. To avoid such an adverse impact, tool engineers should be very resourceful when designing the inserts intended for fine grinding.

An important factor regarding tooth accuracy loss is the insert pocket in a cutter has its own dimensional and form tolerances. As a result, even for ideally precise inserts, teeth protrusion will vary . Of course, the varying lays within acceptable limits, although it cannot ensure extra fine surface finish when compared to grinding. A way to overcome this problem is by using a fly cutter that carries only one insert. The fly cutter that is successfully used in various milling applications facilitates a smooth and clean cut, providing excellent surface texture parameters. But then again, productivity in this case is far below multi-tooth indexable face mills.

How to solve a difficult situation and find an acceptable balance between surface quality and productivity? The cutting tool manufacturer has developed different ways to answer.

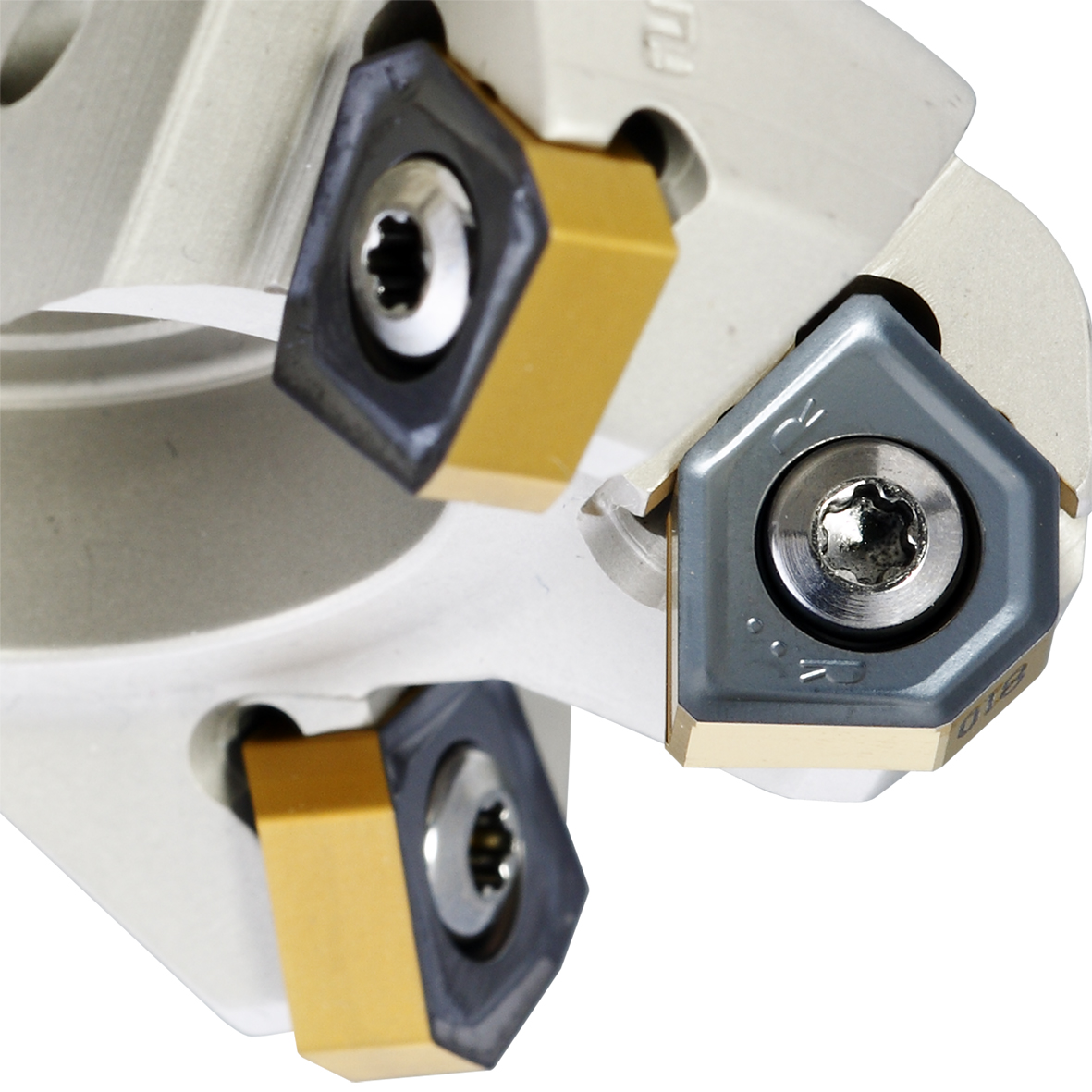

An integrated wiper flat with a specially shaped minor cutting edge is a classical element of various milling inserts. Its width should be greater than the feed per revolution. Despite being called flat, the minor edge sometimes has a complex geometry to compensate a negative effect of wear development. When an insert is mounted on a cutter, the wiper flat sits parallel to the machined surface. Hence, the surface will be formed by the most protruding insert of the cutter. Introducing a wiper flat in an insert design is an effective way to improve surface finish. And even today, rough milling inserts may have an integrated wiper (Fig. 1).

ISCAR's DOVEIQMILL family face mill carries double-sided inserts with a wide wiper flat. These tools are intended for rough and semi-rough milling with surface roughness that usually features semi-finish to finish passes. The DOVEIQMILL cutters have successfully delivered the hopes of their designers – and the adoption of the cutters in various processes resulted in cancelling finish milling operations. The cutters provide roughness Ra up to 0.4 µm (16 µin) when milling steel and cast iron.

Increasing the number of teeth in big-diameter face mills and fine pitch cutters determines the appropriate growth of the integrated wiper width, which has a natural bound due to design and dimensional limitations. In such cases, a high surface finish can be achieved with the use of a specially designed wiper insert (or two inserts for large-sized tools), whereby the wiper flat is significantly wider than the standard one. This insert is mounted in the same pocket but protrudes several tenths of a millimeter (hundredths of an inch) axially relative to the standard insert (Fig. 2).

Very good results can be reached by applying adjustable milling cutters that utilize different mechanisms to adjust the position of an insert cutting edge within very strict limits (only several microns). But the beneficial adjustability of cutting tools also has a flip side as well; it is spider work, which takes time.

A desirable solution looks like a tool that after mounting an insert has no adjusting requirements needed to achieve high surface quality grade. That is why improving accuracy and advanced geometries remain the mainstream in updating indexable cutters for finish face milling.

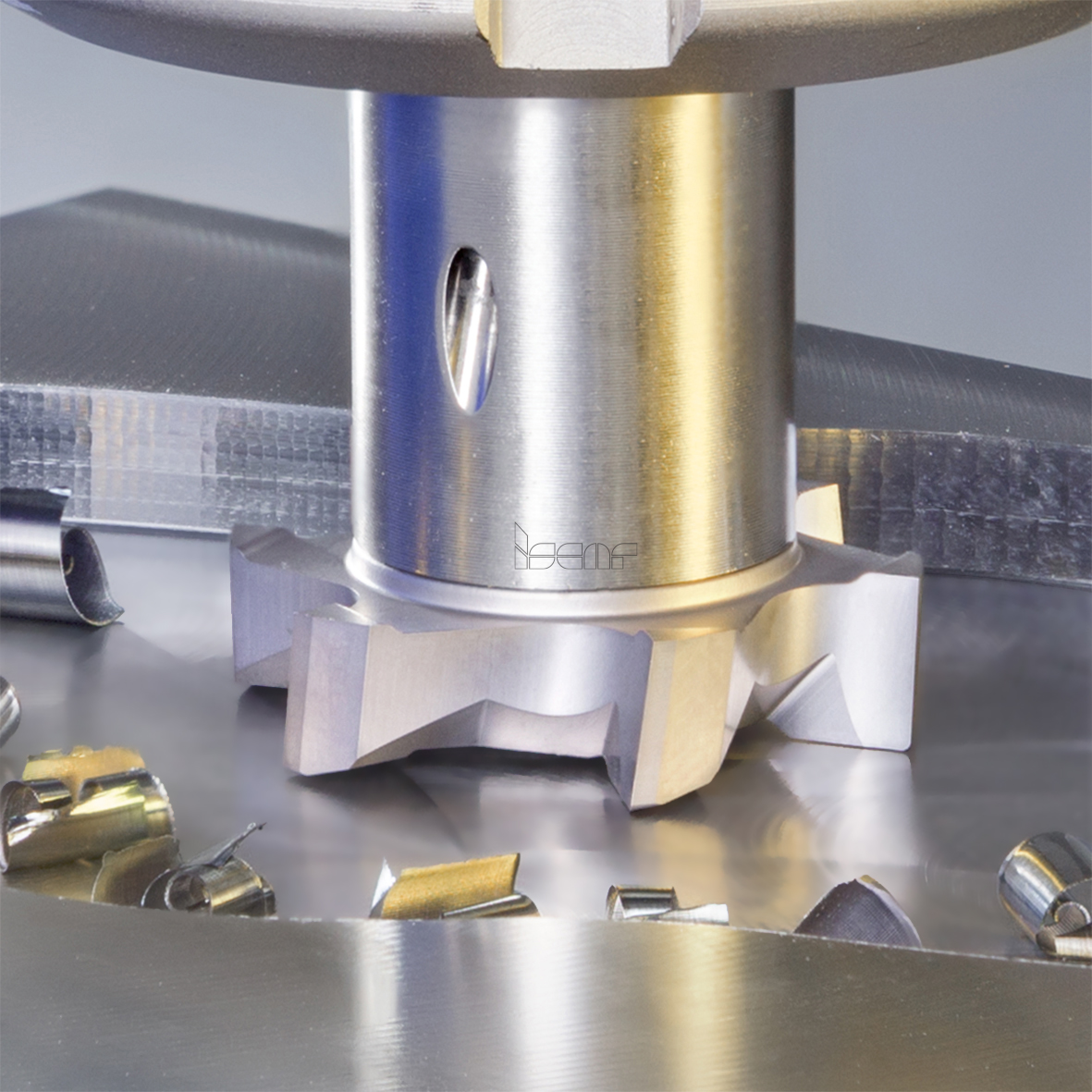

At the same time, cutting tool manufacturers offer unique solutions that attract attention with their originality. An example is ISCAR's TANGFIN family of milling cutters with tangentially clamped inserts with wide integrated wiper flats (Fig. 3). The inserts are positioned in a TANGFIN cutter with a gradual displacement in both radial and axial directions, and therefore, each insert cuts a small section of the machined material providing an extra fine surface finish with roughness Ra up to 0.1 μm (4 μin).

For ensuring a high surface quality in milling relatively small faces, mainly bounded by shoulders, ISCAR developed dedicated exchangeable solid carbide heads in a diameter range of 12-50 mm (.472-2.000 in) for its MULTI-MASTER and T-FACE families (Fig. 4). The heads are fully ground and provide high precision, facilitate a sharp cutting edge, and enable a greater number of teeth when compared to mills with indexable inserts of the same diameter. In combination, these features guarantee high-performance finish milling.

A tendency to decrease machining allowance due to the active introduction of technologies for precise workpiece production and 3D printing makes the issue of obtaining a high surface finish by face milling particularly relevant. Can toolmakers find a prompt, simple, and effective answer to the new needs of manufacturing? The near future will tell.