Page 9 - machining_titanium_05_2019

P. 9

MACHINABILITY OF TITANIUM

There a widespread belief that titanium is like austenitic stainless steel in

terms of its machinability. This may be true when relating to commercially pure

titanium and also, with some assumption, α- or even α-β-alloys; however, it is

fundamentally wrong with respect to the treated β- and near-β- alloys.

In general, titanium alloys (which we will refer to as titanium and specify their composition, grade MACHINABILITY OF TITANIUM

and properties separately where necessary) are hard-to-machine materials and their machinability

depends on various factors: chemical composition, hardness, method of treatment.

The main difficulties in cutting titanium are the following:

• Intensive heat generation leads to excessive adhesive wear of cutting edge.

• Low heat conductivity results in poor heat transfer and slowing heat dissipation

down. Therefore, cutting edge experiences considerable thermal loading.

• “Springiness” of titanium due to low modulus of elasticity contributes to

vibrations and worsens machining accuracy and surface finish.

The mentioned factors significantly reduce tool life and affect performance.

The averaged data in Table 2 allows estimating machinability of titanium

compared with other groups of basic engineering materials.

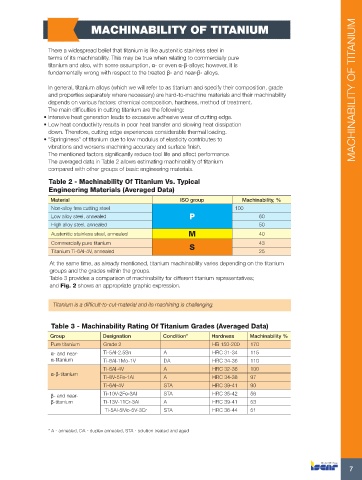

Table 2 - Machinability Of Titanium Vs. Typical

Engineering Materials (Averaged Data)

Material ISO group Machinability, %

Non-alloy free cutting steel 100

Low alloy steel, annealed P 60

High alloy steel, annealed 50

Austenitic stainless steel, annealed M 40

Commercially pure titanium S 43

Titanium Ti-6Al-4V, annealed 25

At the same time, as already mentioned, titanium machinability varies depending on the titanium

groups and the grades within the groups.

Table 3 provides a comparison of machinability for different titanium representatives;

and Fig. 2 shows an appropriate graphic expression.

Titanium is a difficult-to-cut-material and its machining is challenging.

Table 3 - Machinability Rating Of Titanium Grades (Averaged Data)

Group Designation Condition* Hardness Machinability %

Pure titanium Grade 2 HB 150-200 170

α- and near- Ti-5Al-2.5Sn A HRC 31-34 115

α-titanium Ti-8Al-1Mo-1V DA HRC 34-36 110

Ti-6Al-4V A HRC 32-36 100

α-β-titanium Ti-8V-5Fe-1Al A HRC 34-38 97

Ti-6Al-4V STA HRC 39-41 90

β- and near- Ti-10V-2Fe-3Al STA HRC 35-42 56

β-titanium Ti-13V-11Cr-3Al A HRC 39-41 53

Ti-5Al-5Mo-5V-3Cr STA HRC 36-44 51

* A - annealed, DA - duplex annealed, STA - solution treated and aged

7