Page 9 - HOLE MAKING CATALOG p383-544

P. 9

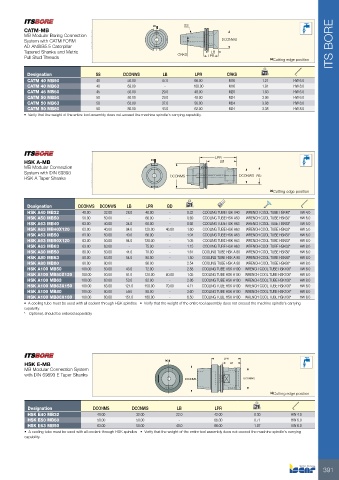

CATM-MB (a) SS ITS BORE

MB Modular Boring Connection

System with CATM FORM CRKS DCONWS

AD ANSIB5.5 Caterpillar LB

Tapered Shanks and Metric LPR (a)Cutting edge position

Pull Stud Threads

kg

Designation SS DCONWS LB LPR CRKS

M16 1.21 HW 6.0

CATM 40 MB50 40 50.00 47.0 66.00 M16 1.91 HW 8.0

CATM 40 MB63 M20 1.83 HW 6.0

40 63.00 - 100.00 M24 3.06 HW 6.0

M24 3.08 HW 8.0

CATM 45 MB50 45 50.00 29.0 48.00 M24 3.38 HW 8.0

CATM 50 MB50 50 50.00 29.0 48.00

CATM 50 MB63 50 63.00 37.0 56.00

CATM 50 MB80 50 80.00 43.0 62.00

• Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying capability.

HSK A-MB (a) LPR

MB Modular Connection LB

System with DIN 69893 DCONMS

HSK A Taper Shanks DCONWS BD

(a)Cutting edge position

Designation DCONMS DCONWS LB LPR BD kg

HSK A40 MB32 40.00 32.00 28.0 48.00 - 0.32 COOLING TUBE HSK A40 WRENCH COOL TUBE HSK40* HW 4.0

HSK A50 MB50 50.00 50.00 - 66.00 - 0.69 COOLING TUBE HSK A50 WRENCH COOL TUBE HSK50* HW 6.0

HSK A63 MB40 63.00 40.00 60.00 - 0.92 COOLING TUBE HSK A63 WRENCH COOL TUBE HSK63* HW 5.0

HSK A63 MB40X120 63.00 40.00 34.0 120.00 46.00 1.60 COOLING TUBE HSK A63 WRENCH COOL TUBE HSK63* HW 5.0

HSK A63 MB50 63.00 50.00 94.0 66.00 - 1.04 COOLING TUBE HSK A63 WRENCH COOL TUBE HSK63* HW 6.0

HSK A63 MB50X120 63.00 50.00 40.0 120.00 - 1.05 COOLING TUBE HSK A63 WRENCH COOL TUBE HSK63* HW 6.0

HSK A63 MB63 63.00 63.00 94.0 75.00 - 1.15 COOLING TUBE HSK A63 WRENCH COOL TUBE HSK63* HW 8.0

HSK A80 MB50 80.00 50.00 70.00 - 1.61 COOLING TUBE HSK A 80 WRENCH COOL TUBE HSK80* HW 6.0

HSK A80 MB63 80.00 63.00 - 80.00 - 1.50 COOLING TUBE HSK A 80 WRENCH COOL TUBE HSK80* HW 8.0

HSK A80 MB80 80.00 80.00 44.0 86.00 - 2.54 COOLING TUBE HSK A 80 WRENCH COOL TUBE HSK80* HW 8.0

HSK A100 MB50 100.00 50.00 54.0 72.00 - 2.58 COOLING TUBE HSK A100 WRENCH COOL TUBE HSK100* HW 6.0

HSK A100 MB50X120 100.00 50.00 120.00 60.00 1.05 COOLING TUBE HSK A100 WRENCH COOL TUBE HSK100* HW 6.0

HSK A100 MB63 100.00 63.00 - 82.00 - 2.86 COOLING TUBE HSK A100 WRENCH COOL TUBE HSK100* HW 8.0

HSK A100 MB63X150 100.00 63.00 43.0 150.00 70.00 4.71 COOLING TUBE HSK A100 WRENCH COOL TUBE HSK100* HW 8.0

HSK A100 MB80 100.00 80.00 91.0 88.00 - 3.60 COOLING TUBE HSK A100 WRENCH COOL TUBE HSK100* HW 8.0

HSK A100 MB80X180 100.00 80.00 53.0 180.00 - 6.50 COOLING TUBE HSK A100 WRENCH COOL TUBE HSK100* HW 8.0

121.0

59.0

151.0

• A cooling tube must be used with all coolant through HSK spindles • Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying

capability.

* Optional, should be ordered separately

HSK E-MB (a) LPR

MB Modular Connection System DCONMS LB

with DIN 69893 E Taper Shanks

DCONWS

(a)Cutting edge position

Designation DCONMS DCONWS LB LPR kg

HSK E40 MB32 40.00 32.00 22.0 42.00 0.30 HW 4.0

HSK E50 MB50

50.00 50.00 - 66.00 0.71 HW 6.0

HSK E63 MB50

63.00 50.00 40.0 66.00 1.87 HW 6.0

• A cooling tube must be used with all coolant through HSK spindles • Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying

capability.

391